Textile supply chain traceability is becoming essential in the industry today. Customers want to know where products come from, governments are bringing in new rules, and brands need better ways to manage their operations. Tracking your product’s journey from raw material to finished garment helps you build trust, follow the rules, and stay ahead in a competitive market.

The supply chain management (SCM) market in textiles is expected to grow from USD 2.75 billion in 2023 to USD 5.39 billion by 2031 at a CAGR of 9.71%.

What Is Textile Supply Chain Traceability?

When you hear “traceability” in the textile industry, think of it as knowing exactly where your products come from and how they are made. Supply chain traceability helps you follow every step of your textile’s journey from raw material sourcing to manufacturing, shipping, and finally to your retail shelves.

Today’s traceability isn’t about paperwork or trust alone. It’s powered by digital identity systems, verifiable credentials, and blockchain technology. These tools let you verify each supplier’s claims in real-time and create a transparent record that no one can tamper with.

Here’s what traceability looks like in practice:

- You know which farm grew your cotton, and whether it was organic.

- You can confirm that your dyes and chemicals meet sustainability standards.

- You track your fabrics as they move through processing units, mills, and factories.

- You verify that your finished garments aren’t mixed with counterfeit or unsourced materials.

This is not just about compliance, it’s about protecting your brand’s story. When a customer asks, “Where was this made? Who made it? Was it done ethically?” you have answers backed by data, not just words.

Traceability also helps you avoid greenwashing. Instead of vague claims like “eco-friendly” or “responsibly sourced,” you show real proof of product origin verification and ethical sourcing.

Why Traceability Is No Longer Optional for Textile Brands

If your brand doesn’t have supply chain traceability today, you’re taking a risk both for your reputation and your business. The textile industry is under more pressure than ever to be transparent, sustainable, and ethical. Customers, regulators, and partners all want the same thing: proof.

Customers Demand Transparency

Your customers no longer accept vague sustainability claims. They expect to know:

- Where the cotton in their t-shirt was grown.

- Whether the workers who made their clothes were paid fairly.

- If the dyes and fabrics used are safe for the planet.

Without traceability, you can’t confidently answer these questions. And if you can’t, your customers will choose a brand that can.

Greenwashing Is Being Exposed

Brands that made false or exaggerated sustainability claims are being called out. Regulators in Europe and other regions are cracking down on greenwashing. If you can’t prove your claims like saying your products are “eco-friendly” or “ethically sourced” — you risk legal fines, negative press, and losing customer trust.

Traceability lets you replace marketing claims with verifiable facts. Instead of hoping no one asks, you’re ready when they do.

Counterfeit Risks Hurt Your Brand

Counterfeit textiles and unauthorized materials can sneak into your supply chain without traceability. This hurts your brand’s quality, reputation, and revenue. With end-to-end traceability, you know exactly what’s coming from your suppliers and where it’s going.

Business Benefits of Supply Chain Traceability

Supply chain traceability isn’t just about avoiding risks — it’s about unlocking real business value. When you make your textile supply chain transparent, you gain a competitive edge and build a brand your customers and partners can trust.

Win Consumer Trust with Verified Product Origins

Modern consumers want to support brands that share their values. Traceability lets you show them:

- Where your textiles come from.

- How they are made.

- Who was involved in the process.

This level of transparency builds loyalty. You’re no longer just telling a sustainability story — you’re proving it with verifiable data.

Achieve Sustainability Labels and Certifications Faster

Traceability makes it easier to qualify for globally recognized sustainability labels, such as GOTS, OEKO-TEX, and Fair Trade. When you can show verifiable credentials at every step of your supply chain, audits become smoother and compliance faster.

These labels don’t just improve your brand image — they open doors to new markets and eco-conscious customers.

Reduce Risks in Your Textile Supply Chain

Without visibility, you’re vulnerable to hidden risks:

- Suppliers changing materials without your knowledge

- Unethical labor practices going unnoticed

- Counterfeit raw materials entering your products

Traceability software helps you monitor every supplier and material in real time, reducing the chance of surprises that damage your reputation or cause legal trouble.

Strengthen Ethical Sourcing and Compliance

Traceability keeps your brand aligned with evolving global regulations on sustainability and ethical sourcing. As governments increase compliance standards (especially in the EU and US), traceability helps you stay ahead of the curve and avoid costly fines.

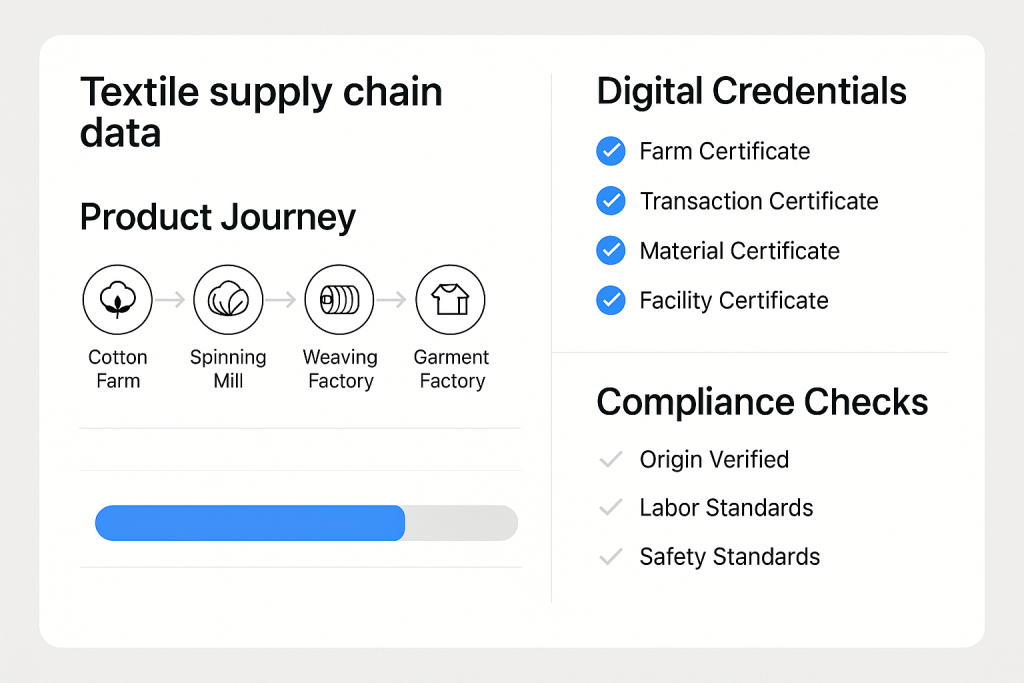

How Traceability Works: From Raw Material to Retail

Let’s break down how traceability works in a textile supply chain. It’s simpler than you might think when you use the right technology.

Step 1: Map Your Supply Chain

The first step is to identify all your suppliers, from raw material producers to manufacturers, dyeing units, logistics partners, and retailers.

You can’t trace what you haven’t mapped.

Ask your partners questions like:

- Where do the raw materials come from?

- Which processes happen at each stage?

- Who are the intermediaries between raw material and final product?

Step 2: Verify Each Step with Digital Credentials

Once your supply chain is mapped, the next step is to add verifiable digital credentials at every stage. Think of these as digital certificates that confirm:

- This cotton was grown organically.

- This dyeing process meets sustainability standards.

- This factory follows ethical labor practices.

Technologies like blockchain and digital identity platforms make this process tamper-proof and transparent. These credentials create a digital trail that auditors, partners, and even your customers can verify.

Step 3: Get Real-Time Visibility Across Production and Logistics

Traceability software helps you track the movement of goods across suppliers and geographies. You can see where your fabrics are, who handled them last, and what process they underwent — all in real-time.

Instead of chasing updates via spreadsheets or emails, you have end-to-end supply chain visibility on one platform.

Step 4: Example — Organic Cotton Traceability Using Blockchain

Imagine your brand sources organic cotton from India. With blockchain-powered traceability:

- The cotton farm issues a digital certificate of origin.

- The spinning mill adds a credential verifying ethical labor.

- The dyeing unit confirms the use of certified dyes.

- Each step is recorded on the blockchain, creating a transparent history that can’t be altered.

When the final garment reaches your store, you can prove its ethical journey to your customers instantly.

Common Myths About Traceability (Debunked)

When you first hear about textile supply chain traceability, you might think it’s too complex or only for big luxury brands. But that’s no longer true. Let’s clear up some of the most common myths.

Myth #1: “Traceability Is Too Expensive”

Reality: Modern traceability platforms are affordable and scalable, even for mid-sized brands.

Cloud-based solutions, blockchain, and verifiable credentials have reduced costs dramatically. Instead of large upfront investments, you can start small and expand as your supply chain grows.

Plus, consider the cost of not having traceability: lost sales from damaged brand trust, compliance fines, or product recalls. Traceability protects your business.

Myth #2: “It’s Only for Luxury or Sustainable Brands”

Reality: Today, traceability is expected across the entire fashion industry, not just high-end or eco-focused brands.

Fast fashion, private labels, and mainstream retailers are adopting traceability to meet customer expectations and global regulations.

No matter your market, transparency boosts your competitive edge.

Myth #3: “Our Suppliers Won’t Cooperate”

Reality: More suppliers now expect traceability requests from the brands they work with. In fact, many are already using digital tools to track their own compliance and sustainability efforts.

If you communicate the value clearly such as helping them win new business and meet industry standards — they’ll likely be open to collaboration.

Choosing the Right Traceability Solution for Your Brand

Not all traceability tools are the same. The right solution fits your supply chain, scales with your growth, and makes compliance easy without adding complexity for your team.

When evaluating traceability solutions, look for these key features:

End-to-End Supply Chain Visibility

The solution should give you a clear, real-time view from raw material to finished product. You should be able to track every supplier, production stage, and shipment without manual work. Look for systems that let you trace:

- Raw materials (cotton, wool, synthetics)

- Processing (spinning, dyeing, finishing)

- Assembly and logistics

- Retail and post-sale

Verifiable Digital Credentials at Every Step

A strong traceability system uses verifiable credentials or digital certificates to prove each step in the supply chain. These credentials should be tamper-proof (blockchain-based, when needed) and easy to share with auditors, partners, and customers.

This replaces trust-based supply chains with data-backed transparency.

Easy Integration with Your Existing Systems

You don’t need to rebuild your operations from scratch. The right traceability software integrates with your:

- Inventory management

- Supplier portals

- Sustainability reporting tools

- Compliance systems

Look for solutions with open APIs, plug-and-play modules, or prebuilt connectors for textile industry platforms.

Example Use Cases in Sustainable Fashion Traceability

- A mid-size fashion brand tracks recycled polyester origins to meet EU sustainability requirements.

- An organic clothing startup uses blockchain credentials to prove farm-level sourcing to its Gen Z customers.

- A premium denim brand implements traceability software to monitor ethical labor practices in Southeast Asia.

What’s Next for Traceability in the Textile Industry?

Traceability in textiles is evolving fast. What started as a compliance-driven process is now becoming a core part of competitive strategy. Here’s where the industry is heading and how your brand can stay ahead.

Rise of Verified Sustainability Labels

Expect sustainability labels to become more data-driven and verifiable. Regulatory bodies and industry groups are already working on traceability-backed certifications that require digital proof, not just supplier declarations.

If your supply chain has verified data at every step, you’ll qualify faster for:

- Organic, recycled, and low-impact material labels

- Ethical labor certifications

- Carbon footprint disclosures

Soon, brands without proof will struggle to win trust and shelf space.

Traceability as a Brand Differentiator

Forward-thinking textile brands are using supply chain transparency as a marketing advantage.

Imagine letting your customers scan a QR code on a garment and instantly see its full ethical journey from organic farm to retail store.

This kind of transparency doesn’t just meet compliance needs — it builds emotional loyalty.

Role of Verifiable Digital Credentials

What They Are:

Verifiable digital credentials are cryptographically secure digital documents that prove the authenticity, origin, and compliance of products or entities in the supply chain.

Benefits:

- Fraud Prevention: Immutable records reduce counterfeiting and unauthorized changes.

- Regulatory Compliance: Instantly verifiable certifications and documents streamline audits and regulatory checks.

- Interoperability: Enable seamless data exchange between diverse supply chain actors, supporting global operations.

Recognizes traceability as a top priority for supply chain leaders, especially in ESG and sustainability software, and highlights the growing adoption of traceability platforms among global brands.

Future Trends: AI-Powered Supply Chain Monitoring

The next evolution is real-time, AI-powered traceability. These systems won’t just track where your textiles are — they’ll predict risks, identify bottlenecks, and recommend actions.

Expect features like:

- Predictive alerts for supply chain delays or ethical risks

- Automated compliance reporting

- Enhanced fraud detection for counterfeit raw materials

Brands that adopt these tools early will stay ahead of both regulation and customer expectations.

Ready to Make Your Textile Supply Chain Transparent and Trustworthy?

If you’re looking to build a sustainable, ethical, and fraud-resistant textile brand, supply chain traceability is no longer optional.

It’s the key to protecting your brand’s integrity, winning customer trust, and staying compliant in a fast-changing industry.

At Everycred, we help textile brands just like yours turn traceability from a challenge into a competitive edge.

From verifying product origins to preventing fraud and greenwashing, our digital trust platform has helped leading fashion and textile companies build transparent, ethical supply chains.

With Everycred’s technology, you can:

- Prove the authentic origin of your materials using verifiable credentials.

- Prevent fraud and counterfeiting across your suppliers.

- Build digital trust with your customers, partners, and regulators.

- Achieve real-time visibility from raw materials to finished products.

Start Your Traceability Journey Today

Don’t wait for the next compliance deadline or brand risk incident. Start small, scale fast:

- Map your supply chain.

- Add verifiable credentials step by step.

- Build a future-proof, fraud-resistant supply chain with Everycred.

We’ve already helped other textile brands overcome supply chain fraud risks and build digital trust with their stakeholders. Now, it’s your turn.

Fill out the inquiry form today to book your free demo with Everycred.

Let’s build a supply chain your customers and your future can trust.

11th July, 2025

11th July, 2025